Q: How to choose the right inspection equipment for your parts and production process?

A: Generally, the measuring equipment that is truly suitable for users is the one that can meet their specific tolerance requirements, but this does not mean that every user needs a super-high-precision measuring machine.When the equipment can meet the user's current and future tolerance requirements, this is the most suitable measuring equipment for their parts and processes.

Next, let's talk about some examples of measuring components to understand the real needs of customers and what type of measuring machine is the most suitable measuring tool.

When the machine meets your tolerance requirements, it is the most suitable measuring machine for your workpiece and process.

Q: What workpieces do you want to measure and what accuracy do you want to achieve?

A: What types of components does your company produce?Do you produce plastic parts, castings, or machine parts?Do you focus on multi-variety/small-batch prototype design?Are there any defense components or aerospace components involved?The answers to these questions will affect your choice of measuring equipment, whether it is a portable handheld scanner or a high-precision bridge measuring machine.Each answer implies a different solution.The solution that suits you will always provide reliable and stable results and help you control the quality process.That's why Rhine offers a complete portfolio of metrology solutions. We can meet any measurement needs you have.

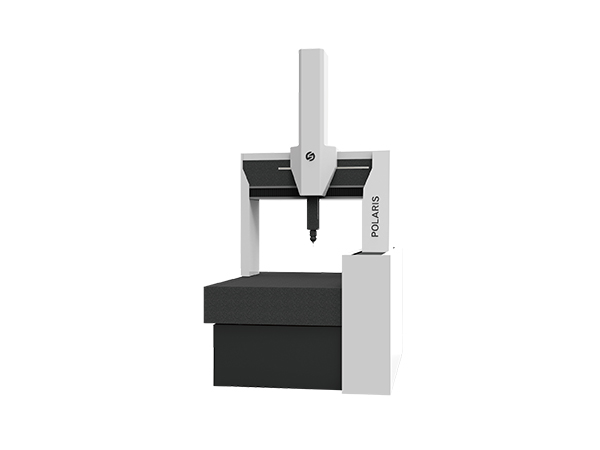

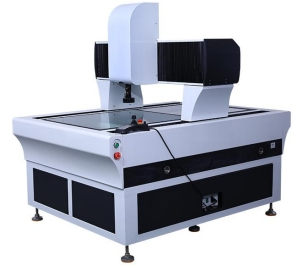

Measuring machines - bridge, horizontal arm, gantry, workshop and optical three-dimensional measuring machines, as well as CT - computed tomography, portable articulated arm and handheld scanners, equipped with Rhine's self-developed coordinate measuring software and optical probes to ensure a complete solution.

Q: Faced with numerous options, what is the best choice for your company?

A: The solution you choose depends on the characteristics of the product itself.For example, if you have flexible parts and don't want traditional contact probes to touch the parts, Rhine will provide you with a solution using an optical 3D line laser scanning probe on a traditional bridge CMM.

Q: Is the accuracy stable?

A: Can the solution maintain long-term stability and meet your future needs?The design and manufacturing of Rhine Systems allows users to use it for decades.Many of our customers' equipment has been in use for 20 to 30 years and still has reliable results and accurate data!This is due to the reliable German design and system construction achieved by Rhine's experienced team in the factory.This means that your Rhine coordinate measuring machine will be stable and accurate after 20 to 30 years with proper maintenance and care.Regardless of what parts you are manufacturing now and in the future, or what you are going to engage in that are currently unknown, one thing is for sure: no matter how large, small, or challenging your parts are, our machines will ensure the reliability and accuracy you need for the next few years.

The most important thing

Most importantly, you can purchase a coordinate measuring machine that far exceeds the accuracy required for your work, but this does not mean that it is your best tool.

When considering purchasing a "three-dimensional measuring machine", remember that you need to consider the "highest-precision three-dimensional measuring machine" that can meet your current and future measurement requirements.