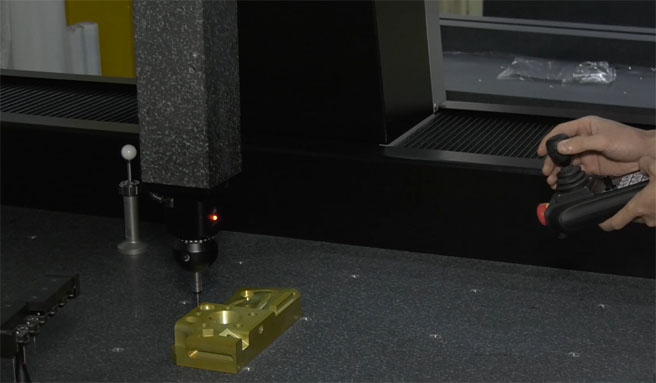

Efficient detection of defects in automotive stamping parts using a bridge type stable structure of a coordinate measuring machine

For the detection of defects in automotive stamping parts, measuring instruments such as gauges, steel rulers, feeler gauges, and surface difference meters are commo.......

Common Hardware Instruments and Tools in Precision Measurement

In the production of modern industry, we often use various detection instruments, among which precision measurement instruments are the main ones......

Differences between fully automatic and manual imagers

Image measuring instruments can be divided into automatic image measuring instruments and hand operated image measuring instruments. The differences between ......

Introduction to Three Coordinate Measuring Needle

The standard definition of the total length of a three coordinate measuring needle is the length from the rear mounting end face of the measuring needle to the center of the measuring ball. Effective Working Length (EWL) The effective working length is the distance from the center of the measuring ball to the interference point between the measuring rod and the measured target when measured in the normal direction of the part

What is the difference between a CMM and a profilometer?

The profiler consists of a granite flat plate, a workbench, sensors, a drive box, a display, a computer, and a printer. During measurement, different positions of the measured parts can be selected, and various measurement lengths can be set for automatic measurement

Maintenance of the Gas Path of the CMM

As compressed air plays a very important role in the normal operation of CMMs, the maintenance and repair of the air circuit is very important. The main items are as follows: 1. Check the pipes and filters before use every day, and drain the water and oil from the filter and the air compressor or air storage tank

Requirements for operators of coordinate measuring instruments

CMM operators should have basic knowledge of computers, and have a certain understanding and familiarity with optical, mechanical, and electronic knowledge. Secondly, the operator should have a professional dedication, be diligent and dedicated, and cannot be limited to simple operations

Selection of Probe Types for CMMs

The probe tip of a CMM is in direct contact with the workpiece. They are typically mounted on the shaft end by synthetic monocrystalline, highly spherical industrial rubies. Ruby is a very hard ceramic material to ensure minimal wear on the touch ball

Factors Affecting the Accuracy of CMMs

In addition to the measurement accuracy error caused by the failure of the CMM itself, there are many factors that may affect the accuracy of the CMM, resulting in measurement errors. Operators should understand these factors to avoid affecting the accuracy of part measurements

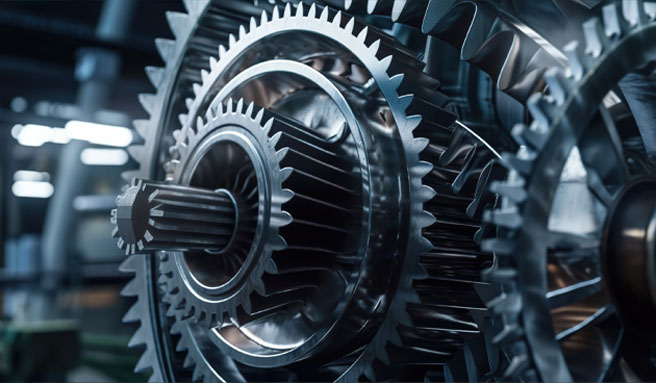

Application of CMM in Engine Manufacturing

An engine is composed of many components of various shapes, and the manufacturing quality of these components is directly related to the performance and life of the engine. Therefore, it is necessary to use CMMs for very precise testing in the production of these components

Application of CMM in Mold Industry

CMM is widely used in the mold industry. It is a modern intelligent tool for design, development, testing, and statistical analysis, and is also an effective tool for ensuring the quality and technology of mold products. CMMs with their high accuracy

CMM Helps Mold Enterprises Improve Core Competitiveness

China is the center of the manufacturing industry and a big country in mold manufacturing. For many years, mold manufacturing, especially private mold enterprises, generally have advanced equipment resources, relatively advanced technology applications, and new technologies can be widely used in the industry