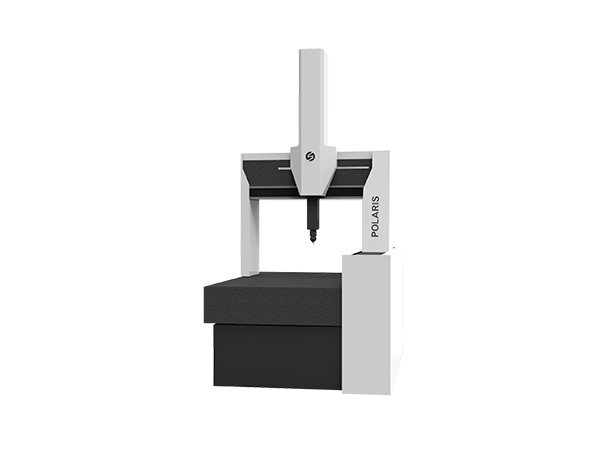

The five-axis machining center has three moving axes (X, Y, Z) and any two rotating axes. Compared to traditional three-axis machining centers, the five-axis linkage technology of the five-axis machining center enables the tool to position and operate in five degrees of freedom when machining geometrically complex workpieces;

As a highly automated intelligent processing equipment, five-axis machining centers are often used in high-end manufacturing;

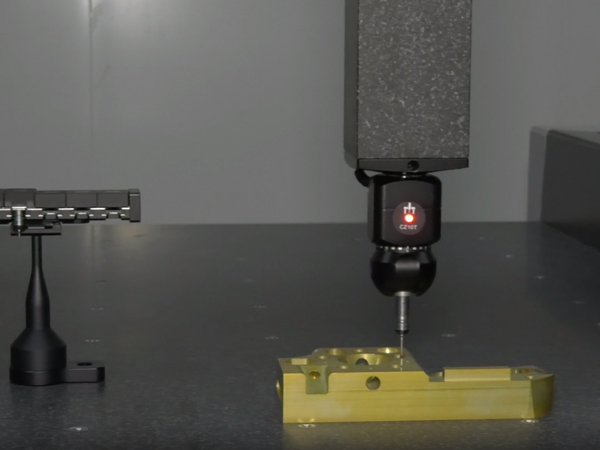

The five-axis machining center is suitable for machining free-form surface body parts, turbine parts and impellers on aircraft and ships;

Workpieces suitable for machining on five-axis machining centers have high degrees of curvature and are difficult to machine with a single fixture. Therefore, five-axis machines can process different sides of the workpiece without changing its position on the machine, greatly improving the efficiency of machining prismatic parts.

The five-axis machining center is currently a particularly effective device for machining non-planar bodies, boxes, and complex cavities;

The five-axis machining center is suitable for aerospace, precision machinery, automotive equipment, high-precision medical equipment and other fields.