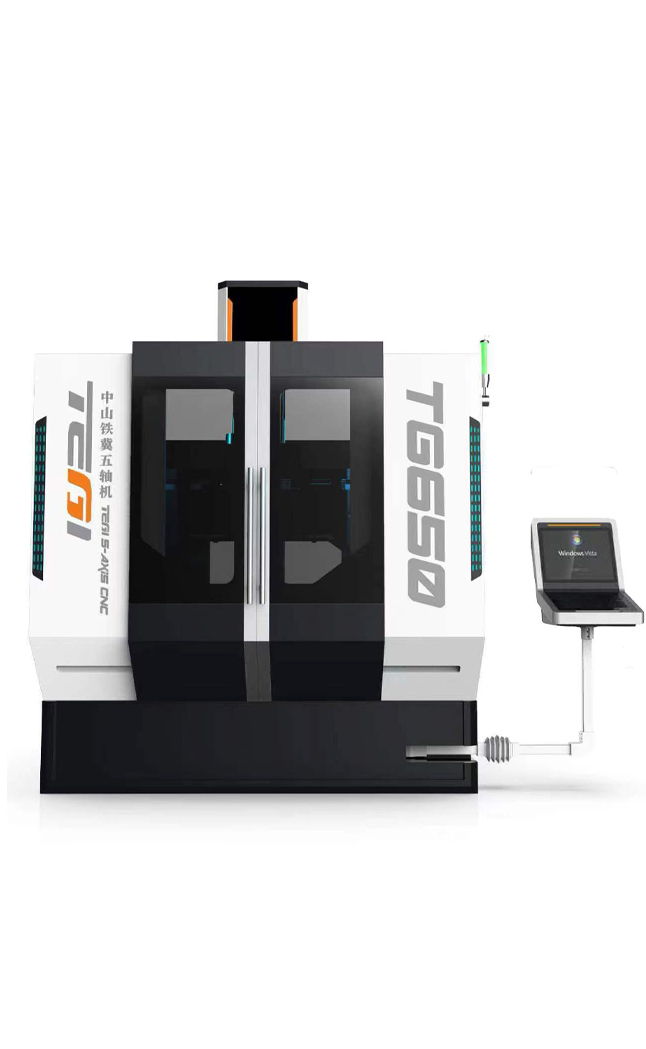

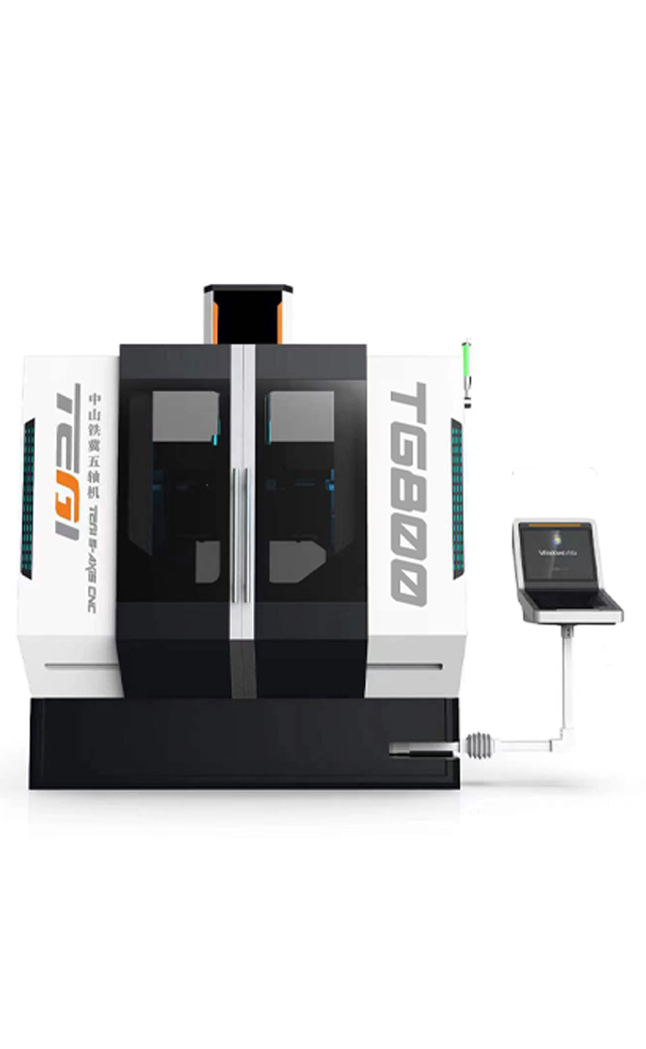

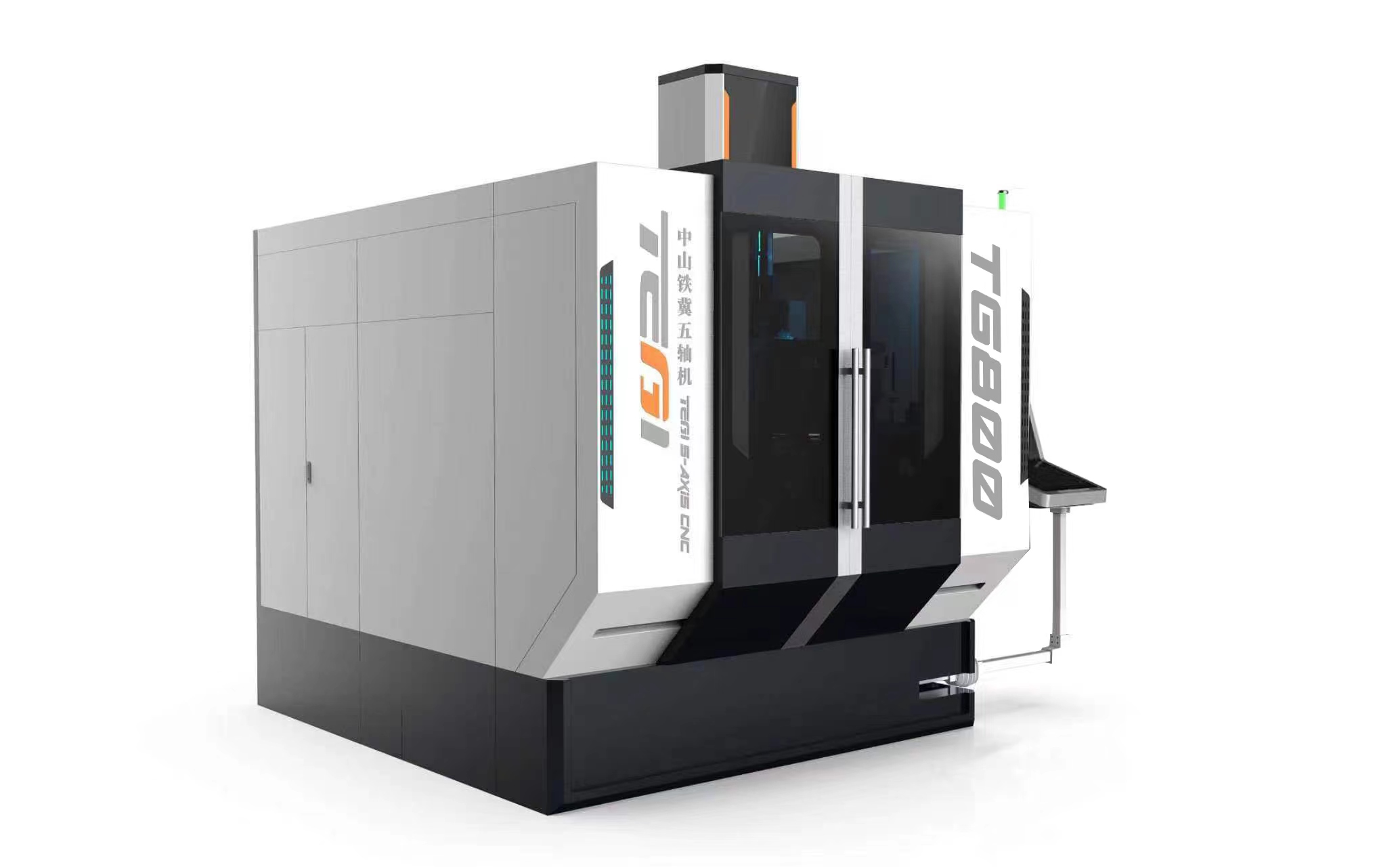

TG800

rotary-table 5-axis machine tool Technical Agreement

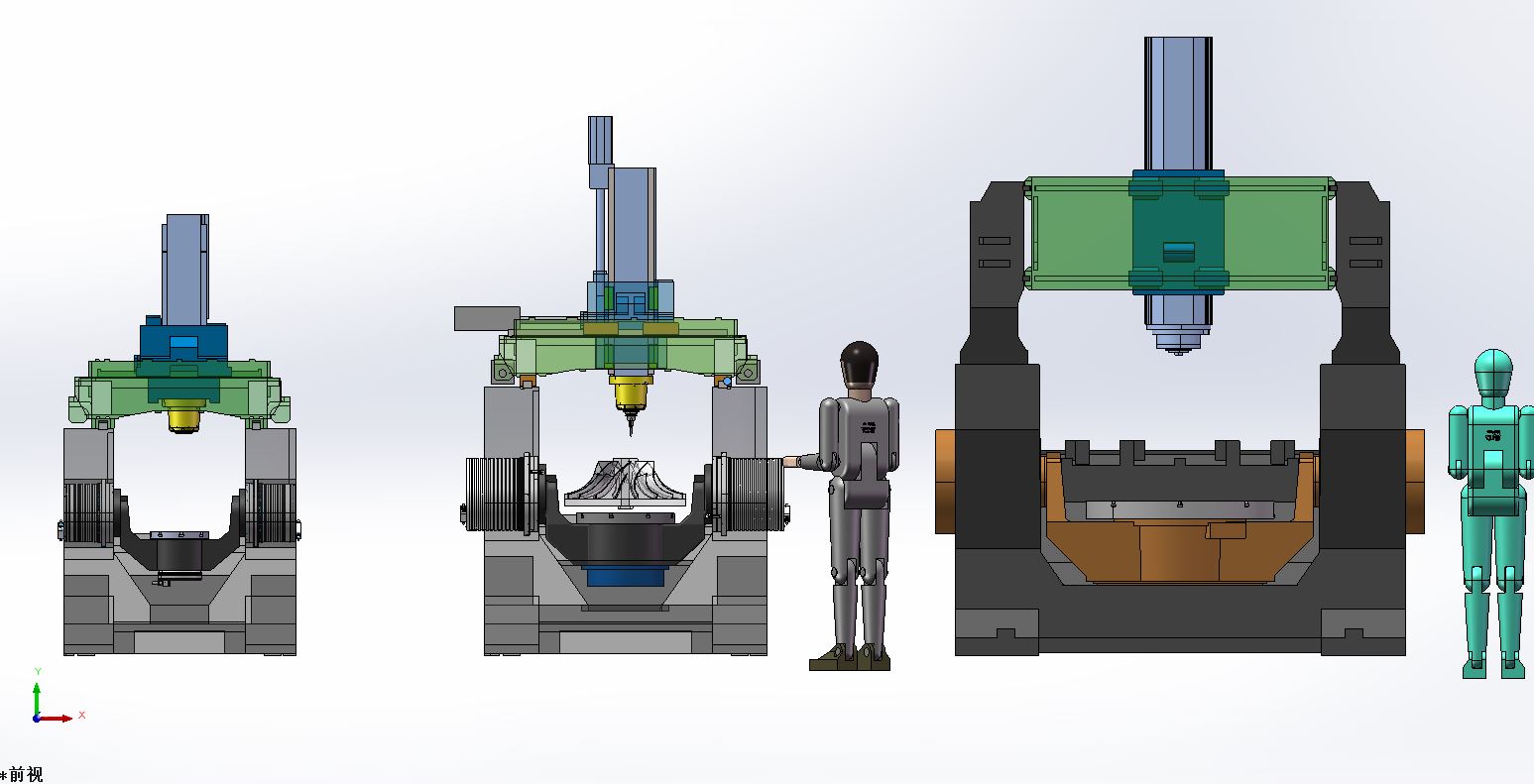

TWO. TG800 TECHNICAL DATA

| Working range | |||

| X/Y/Ztraverse path | 810/1000/600 | Unit:mm | Y:before-A-axis ,450,behind-A-axis ,550 |

| A-center to table | 100 | Unit:mm | |

| Distance spindle to table | Min180-Max780 | Unit:mm | |

| Diameter of the rotary table | φ800 | Unit:mm | |

| Diameter of C-axis maximum rotary space | φ1100 | Unit:mm | |

| Table max load | 1500 | Unit:KG | |

| Motor-spindle | |||

| Cutting-tool interface | HSK-A63 | ||

| Torque S1/S6 | 83/125 | Unit:NM | |

| Speed max | 18000 | Unit:RPM | |

| Power | 30 | Unit:KW | |

| Through-spindle-coolant | available | ||

| NC Swivel-and-rotary table | |||

| A swivel range | ± 140⁰ | ||

| A speed max | 30 | Unit:RPM | |

| C rotary range | N×360⁰ | ||

| C speed max | 100 | Unit:RPM | |

| A motor | DDR ×2 | 2543NM×2 | |

| C motor | DDR | 1210NM | |

| Tool-magazines | |||

| Tool interface | HSK-A63 | ||

| Tool positions | 36把 | ||

| Max. Tool diameter | 80MM | ||

| Max. Tool length | 300MM | ||

| Max. Tool weight | 10KG | ||

| Machine size&weight(not including machine accessories) | |||

| width | 2500 | Unit: mm | |

| length | 4000 | Unit: mm | |

| Height: spindle up & down | 2800~3500 | Unit: mm | |

| weight | About 15 | Unit: Ton | |

| others | |||

| Power | 380v in phase 3 | 150KW | |

| Compressed air | 6-8kgf/cm² | ||

| Machine lubrication | T68 guide rail oil | ||

| Spindle cooling | 5#Spindle oil | ||

| Table cooling | distilled water | ||

THREE. Standard configuration and the major components

| No. | items | quantity | Note |

| 1 | SIEMENS 840D system | 1 set | |

| 2 | Fully enclosed, uncapped, body sheet metal | 1set | |

| 3 | Full-area stainless steel protection in the working area | 1set | |

| 4 | AC 3DDR,A-Axis has 2 DDR | 1set | |

| 5 | Z-axis tool setter | 1 | |

| 6 | HSK-A63/18000rpm Motor-spindle | 1 | |

| 7 | HSK-A63 tool magazines | 1 | |

| 8 | Linear guide:X/Y/Z:55 RG ×1 /55RG ×2/45 RG ×4 | 1set | |

| 9 | Guide screw(double nut)X/Y/Z:R40-16/R40-16×2/R40-16 | 1set | |

| 10 | Centralized automatic lubrication | 1 | |

| 11 | High pressure coolant pump | 2 | |

| 12 | Mist extraction unit | 1set | |

| 13 | Oil and water separation system | 1set | |

| 14 | Chip conveyor | 1set | |

| 15 | Three-color indicator light、High-brightness LED lighting | 1set | |

| 16 | Thermostatic coolers | 1set | |

| 17 | Electric cabinet air conditioning | 1 | |

| 18 | XYZAC, grating scale,Circular encoder for closed-loop control | 1set | |

| 19 | tool case,Supporting tools | 1set |

FOUR. Options

| No. | items | quantity | Note | ||

| 1 | Extension tool magazines | ||||

| 2 | 3D touch probe | ||||

| 3 | Laser tool-measuring unit | ||||

| 4 | safety door latch | ||||

| 5 | automatic door | ||||

| 6 | Automatic ceiling | ||||

| 7 | CNC SYTSTEM | Siemens 840D OR HNC 848 | |||

| 8 | CNC System |

Five-axis anti-collision,DCM | |||

| 9 | Online measurement compensation、3D-ToolComp | ||||

| 10 | 3-D Space compensation | ||||

| 11 | DNC | ||||

| 12 | software service | ||||

| 13 | Post software | ||||

FIVE. Customer Preparations

| No. | items | requirement | Note |

| 1 | Plant foundation | The maximum lifting part weight approximately 20T | |

| 2 | Power cable | 16mm²*3+10mm²*Power supply cord (five-core) | |

| 3 | compressed air | 1.Air source filtration accuracy 100μm2.air pipeinternal diameter 10mm, pressure 6-8kgf/cm²3.Dry filter device | |

| 4 | Equipment oil | TECHNICAL DATA page 4 | |

| 5 | Transportation conditions | 1.transportation way according to the plant and surrounding road conditions2.Meet the net transport size of the maximum component of the machine tool3.Check the lifting method according to the actual height of the plant | |

| 6 | Machine tool operation | 1.Corresponding programming and machine operation technicians2.Programming computer3.cutter, cutter holder,measurement,etc. |