For the detection of defects in automotive stamping parts, measuring instruments such as gauges, steel rulers, feeler gauges, and surface difference meters are commonly used to measure the edge size, profile size, aperture, and hole position of the stamping parts. At the same time, combined with the product's digital simulation, the dimensional status of the stamping parts can be confirmed. However, such manual measurements as the inspector's measurement techniques, clamping sequence, and other manual operations can have a certain impact on the measurement results. Using a three coordinate trigger, scanning, and non-contact detection system, it is possible to accurately measure the hole position and surface dimensions of parts, and complete geometric measurement and quality control of various automotive components.

The mobile bridge type is the most widely used structural form in three coordinates. This structure is characterized by good openness, wide field of vision, convenient lifting and lowering of parts, fast movement speed, and high accuracy. Mars Mobile Bridge CMM is equipped with high-precision guide rails, probe heads, and control systems, and combines computer programs to automatically control the detection process, thereby calculating and outputting measurement results. It supports probe replacement racks, image cameras, and precision turntables. It can detect the dimensions, shapes, and positional relationships of various parts and components, as well as optical scanning measurements of soft materials or complex parts.

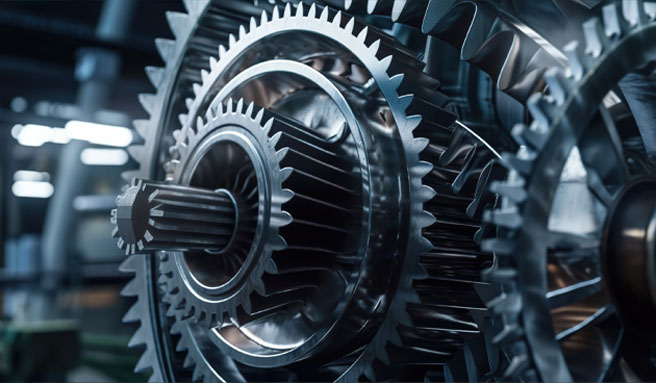

Mars Series Bridge CMM

Mars series bridge type three coordinate measuring machines move in the vertical direction with the Z axis as the main axis. The horizontal beam adopts a German Heidelberg grating ruler, which has high accuracy and long-term stability, is perpendicular to the Y axis and is supported at both ends by two pillars; The air flotation detection safety device ensures that the Z-axis will not fall due to air failure, ensuring the safety of the probe and the measuring base.

Mars Series Bridge CMM

The bridge type fully automatic three coordinate measuring machine moves along the guide grooves of two mutually perpendicular X and Y axes in the horizontal plane and along these two directions. The three XYZ axes measure the spatial coordinates of various points and elements of various components and assemblies to evaluate length, diameter, shape error, position error, etc. Because both ends of the beam are supported by columns, minimum deflection can be obtained and higher accuracy can be achieved than cantilever type. Place the stamping part in the measurement space of a three coordinate measuring machine to obtain the coordinate positions of each measurement point. The measurement software performs mathematical operations based on the spatial coordinate values of these points to calculate the geometric dimensions, shapes, and positions to be measured, thereby completing tasks such as part detection, shape measurement, and process control.